Add to Cart

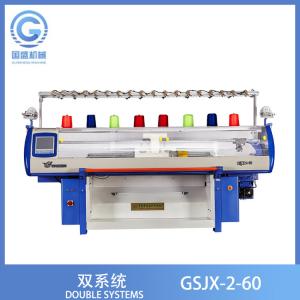

Double System Computerized Sweater Flat Knitting Machine Sweater Hat Scarf Knitting Machine

TOP Sensor

The upper tension device adopts an operation mode that can quickly and easily thread the yarn. During the knitting process, when a big knot is detected, the machine will stop; when a small knot is detected, the machine head will slow down, thereby enhancing

quality management.

Yarn Feeder

We used the Intarsia yarn feeder combination, Two yarn feeding pulleys are placed in each set of yarn feeders to ensure that the yarn enters smoothly without breaking

we use yarn feeders of different structures for the shoe upper machine and the sweater machine.

TAKE DOWN DEVICE

Double stepper motor driven roller

1/ Use two pc 20N / m motors drive the roller

2/ Double-row chain, long-term use will not damage

3/ Planetary gearbox

Knitting bed Shaker Device

Knitting bed shaker with new structure

The special motor-type shaker increases the range of the shaker of the front and rear needle beds, and the short-speed shaker

makes the control and knitting performance of the shaker better. And on the basis of not changing the original size of the flat

knitting machine, the allowable space of the shaker is greatly expanded. In this way, it is easy to realize a new pattern of free

play of 10 twists or multi-stage shakers.

Machine parameter

| GAUGE | 3G,3.5G,3-5-7G,5G,6G,7G,8G,9G,10G,12G,13G,14G,15G,16G |

| SYSTEM | THREE SYSTEM SINGLE CARRIAGE |

| KNITTING WIDTH | 52 INCH |

| KNITTING SPEED | MAX.1.2M/SEC |

| KNITTING FUNCTION | TRANFER,TUCK,MISS,JACQUARD,INTARSIA,HIDE OR APPARENT SHAPING. |

| STITCH DENSITY | STITCH SYSTEM CONTROLLED BY STEPPING MOTOR,32 SECTION STITCH SELECTABLE,ADJUSTABLE SCOPE SUPPORTED BY SUBDIVISION TECHNOLOGY:0-650 |

| RACKING | CONTROLLED BY AC SERVO MOTOR,RACKING WITHIN 2 INCHES AND WITH FINE ADJUSTIING FUNCTION. |

| DRIVE SYSTEM | SYNCHRONOUS BELT DRIVE,AC SERVO SYSTEM |

| NEEDLE SELECTION | CONTROLLED BY COMPUTER,ELECTRIC MAGNET NEEDLE CHOOSE SYSTEM WITH HIGH EFFICIENCY. |

| YARN CARRIER | 2x8YARN CARRIERS ON EACH SIDE OF 4 GUIDE RAILS,SHIFTABLE ON ANY NEEDLE POSITION |

| TAKE DOWN ROLLER | PROGRAMMED INSTRUCTION CONTROLLED BY STEPPING MOTOR,32 SECTION LEVELS SELECTION ADJUSTABLE AREA:0-100 |

| SINKER SYSTEM | ASSIST KNITTING,HAVE VARIOUS RESULTS OF SHAPING AND STOP. |

| PROTECTION SYSTEM | THE MACHINE WILL AUTOMATICALLY ALARM IF YARN BREAKING,FLOAT YARN,REWIND,END OF KNITTING,FAIL OF RACKING,NEEDLE BREAKAGE AND ERROR PROGRAMMING OCCUR ECT. |

| CONTROL SYSTEM | 1,ADOPT LCD SCREEN,INPUT DEVICE:USB,SYSTEM MEMORY 256MB,A GREAT AMOUNT OF DESIGN FILES CAN BE STORED.2,MONITORING MENU,EACH KIND OF OPERATING PARAMETER,CAN BE SHOWN,AND THEY CAN BE ADJUSTED AT ANY TIME WHEN THE MACHINE IS RUNNING.3,DESIGN SYSTEM IS VISUAL AND EASY TO UNDERSTAND AND UPGRAD.4,MULTI LANGUAGE VERSION,THERE ARE CHINESE,ENGLISH ETC. |

| POWER | 220V ,SINGLE-PHASE,HAVE MEMORIZING FUNCTION AT THE POWER-OFF MOMENT |

PRODUCT DETAILS

YARN FEEDER

Yarn feeders can be adjusted according to the knitting width of fabric,also can be adjusted by programmable fine tune according to the carriage’s running speed.

PROBE ALARMING DEVICE

Probe alarming device is a breakthrough as compared with the current monotonous detecting mode where the probes sway from side to side.This device is able to completely,safely and effectively realize the detection and avoid the damaged to the fabrics and other failures.So as to ensure the normalized operation of the machine and increase the working efficiency of knitting process.

YARN TRANSPORTATION DEVICE

The yarn transportation device is installed between the yarn bucket and knitting system,which greatly improves the uneven tension caused by overlong yarn journey,When then yarn is sued up or breakage of yarn takes place due to any reason,the sensor in the yarn transportation device will alarm and the machine stops working.This prevents the broken yarn from entering then knitting area,making the connection of yarn easily and avoiding the damages to the quality of fabrics.

POWER FAILURER PROTECTION

With power failure protection,the machine is able to automatically memorize the data upon power failure the and recover the data when the power is restored,so that the machine can continue the pending work according the programmed patterns,which avoids the waste of yarn ans saves the time,without compromising the quality of the fabrics.